Finishing and Maintaining Wood Floors

Part 1 – Wood Properties

Introduction

Wood possesses a variety of properties that make it a highly desirable flooring material in residential and public buildings. In addition to these unique properties, wood flooring can be installed in various distinctive patterns such as parquet and herringbone. Furthermore, wood floors are attractive and serviceable. As a result, the popularity of new wood floors as well as interest in refinishing old ones continues and has even increased in recent years.

Wood Species

Wood possesses several physical properties which are important to its use as a flooring material. For example, the species of wood selected is one important property since it affects hardness, texture, and color. White and Red Oak (Quercus sp.) is the most common hardwood species used. It is an open grained wood with a beautiful grain pattern. Other open grained hardwood species sometimes used for flooring include pecan and ash. Walnut is sometimes used but it can easily be “dented” by boots and high heels. Close grained hardwoods include beech, birch, and hard maple. Douglas-fir and southern pine are two softwoods species used for flooring. The hardwoods listed are generally more resistant to mechanical wear than the softwoods. The softwoods will certainly give satisfactory performance. By the way, eastern white pine and red pine have been used in the past for flooring but are rarely used now.

Wood Moisture

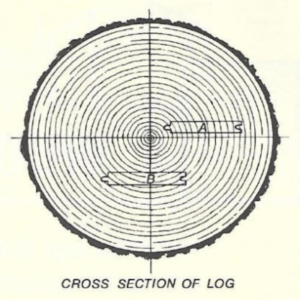

The ability of wood to pick up and lose moisture to maintain an equilibrium with its environment is a critical property when wood is used for flooring. If wood loses moisture after it is installed, shrinkage will occur and cracks will develop between individual boards. At worst, a significant increase in moisture content will cause wood to swell and will result in a buckled floor. I have served as an expert witness in many such cases. When first laid down, the wood should be at the correct moisture content. The moisture content of the wood should be checked with a pinless moisture meter.

The boards are tight against each other when laid down. Then because of excessive moisture in the home (heating will help reduce this moisture), the wood swells and the sides of the boards bear tightly against each other, crushing some of the cells. After a board has been “compression set” in this manner, it never completely recovers. The flooring may now lose moisture after the house is occupied or when the humidity decreases during winter months. The crack which opens up will be about equal to the amount of “compression set” that has occurred. “Compression set” may also occur when the house is unoccupied or unheated for several weeks during cold or damp weather. Foreign matter in the cracks can also continue or increase the amount of compression set. A kitchen floor of exposed boards in which repeated scrubbings cause the cracks to grow wider as the floor grows older, shows the effects of a series of compression sets.

The swelling and shrinking of wood is best controlled by kiln drying wood during manufacturing to the same moisture content as that for the area in which it will be used. A moisture content of about 8 percent in wood is recommended for the Central and Eastern US, 6 percent for the dry Southwestern states and 11 percent for the Southern coastal states.

In addition to properly drying wood during manufacture, it must also be protected from moisture during shipment, storage, and on the job site. Flooring should not be transported on damp, rainy, or snowy days unless fully protected. The exposed ends of boards can rapidly absorb moisture and swell; and then if installed, drying and shrinkage will occur and cracks will open up. Wood can pick up moisture in a similar fashion if stored by the supplier or purchaser in damp locations.

If satisfactory performance is to be expected, the moisture content of wood must also be controlled once it is delivered to the job site. Before the flooring is delivered, the building should be enclosed, and the HVAC system should be operating. Any concrete, masonry and plaster work should be well cured. The building where the flooring will be installed should be maintained above 70 F in the summer and 65 F when the outdoor temperatures are below freezing. Excessive heating, however, should be avoided. These temperatures should help maintain the correct wood moisture content. About four days before installing the wood floors, open the bundles and loosen the piles so that the wood will come to equilibrium within the building or home.

Meet the Author

Dr. Todd Shupe is the President of Wood Science Consulting, LLC. He is a well-recognized expert on wood forensics, wood preservation, wood decay and degradation, and wood species identification. He has a broad background in new product development, quality management, and marketing and sales in both the public and private sectors. For more information please visit DrToddShupe.com.

We welcome your comments below.

Thank you for visiting. We trust that you have enjoyed reading our articles.

Liked this post? Read more below or search for more topics . . .