Should I Use Nails or Screws?

One of the most common questions I have been asked over the years is “Should I use nails or screws?” Nails and screws are the most common fasteners which are most commonly used for wood-based construction and general wood working projects. Most people are confused, which is better for joining materials together, nails or screws?

When selecting fasteners, you need to consider the nature of the job and the materials that are involved. Generally, nails are more popular among carpenters because they are easy to work with and can be rapidly shot from a nail gun. However, when strength is more concern, you need to use screws. This blog will discuss some of the differences between nails and screws.

Composition

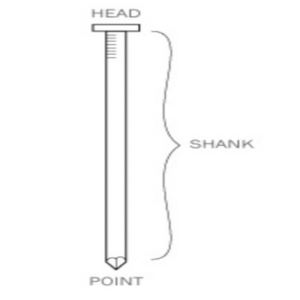

Nails consist of 3 parts; head, shank and point.

- The head of the nail is enlarged and flattened to allow easy hammering.

- The shank is the long thin portion of the nail. Nails hold materials together through the friction created between the shank and the material.

- The nail point is the tapered portion at the end of the shank.

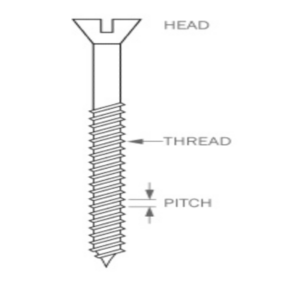

Screws consist of 3 parts; head, threads, pitch

- The head of the screw has a recessed area that accepts a tool, such as a drill or a screwdriver, which turns the screw into place.

- The threads are the helical ridges along the screw, which provide the friction that keeps the two materials together.

- The pitch is the distance between threads.

When to Use?

- Nails

- Furniture that generates sideways pressure, i.e. lateral forces where material would have the tendency to move sideways is when you would use a nail.

- If you are making lightweight furniture and nails are acting as only glue, then you can use nails. For example, if you are making drawer bottom, cabinet framing, etc. then you can use nails.

- Screws

- Furniture that will try and separate from the top or bottom, then you can use a screw.

- Screws are recommended for making furniture of plywood, blockboard, MDF, etc. as it has a good holding strength. When strength is a larger concern, i.e. at all joints, then you can use screws. For example, if you are making a wardrobe, modular kitchen, chair, etc. then you can use screws due to favorable holding strength.

- If you are making long shelves, benches, tables, etc. where length of the furniture is more than 6-7 ft. then you can use screws.

Material

- Nails

- Nails are generally made up of mild steel, although it can be made of aluminum, brass, or many other metals.

- Screws

- Screws are made up of brass, stainless steel, mild steel coated with chromium, etc.

Strength

- Nails

- Nails have higher shear strength compared to screws.

- Screws

- Screws have a much higher tensile strength compared to nails.

Rust Resistance

- Nails

- Nails are generally less resistant to rust.

- Screws

- They are highly resistant to rust and prevent moisture to come in contact with its metal.

Advantages

- Nails

- Nails are cheaper than screws.

- They can be installed faster. Two or four blows from a good hammer and you can drive a nail all the way into the wood.

- Finishing nails can be easily hidden on furniture surface as it has a small head.

- In lightweight furniture, where almost no load is coming, then you can use nails.

- If you accidentally bend a nail by hitting it at the wrong angle, you may be able to hammer it straight again and reuse it.

- Screws

- Screws are very strong.

- The screw is recommended for making furniture of plywood, MDF, etc. as it has a good holding strength.

- They are easier to remove than nails.

- You can decide where exactly to put them in and install them slowly and methodically with the use of drill or screwdriver.

Disadvantages

- Nails

- Nails are not recommended for plywood, blockboard, etc. as when nails are hammered; nails get bent or even split the wood.

- Nails do not have good holding capacity as compared to screws.

- Nails are installed with the use of hammer which requires more force to install. A pneumatic nail gun is an exception.

- Screws

- The head of the screws are usually larger than its body, therefore it becomes difficult to hide it discretely.

- It requires skilled labor for installation.

- It is not flexible as compared to nails.

Cost

- Nails

- They are less expensive than screws. The cost of the nails depends upon the size of nails and materials.

- Screws

- Screws are more expensive than nails. The cost of the screws depends upon the size and material.

Conclusions

From the above comparison on nails vs screws, we can conclude that though nails and screws, both are used for same purpose, screws have more holding strength than nails and hence are always a better option. However, speed and cost also must be considered.

Meet the Author

Dr. Todd Shupe is the President of Wood Science Consulting, LLC. He is a well-recognized expert on wood forensics, wood preservation, wood decay and degradation, and wood species identification. He has a broad background in new product development, quality management, and marketing and sales in both the public and private sectors. For more information please visit DrToddShupe.com.

We welcome your comments below.

Thank you for visiting. We trust that you have enjoyed reading our articles.

Liked this post? Read more below or search for more topics . . .