Wood Cars

Young boys years ago made wooden cars and raced them in the pinewood derby. I recall mine was held in the basement of my home church. My car was fast but not fast enough to win. I never imagined that wood would someday be used to make or fuel cars.

Now, the use of wood in cars has gone one step further. Japanese researchers and auto component makers are working on a material made from wood to help in the assembly of cars. The material weighs just one fifth of steel and can be five times stronger. The material is cellulose nanofibers and could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.

Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs.

Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota’s biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers – made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter).

Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the “Kyoto Process”, under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes.

“This is the lowest-cost, highest-performance application for cellulose nanofibers, and that’s why we’re focusing on its use in auto and aircraft parts,” Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview.

“We’ve been using plastics as a replacement for steel, and we’re hoping that cellulose nanofibers will widen the possibilities toward that goal,” said Yukihiko Ishino, a spokesman at DaikyoNishikawa, which counts Toyota Motor Corp and Mazda Motor Corp among its customers.

Automakers are also using other lightweight substitutes. BMW uses carbon fiber reinforced polymers (CFRPs) for its i3 compact electric car as well as for its 7 series, while high-tensile steel and aluminum alloys are currently the most widely used lightweight options because they are cheaper and recyclable.

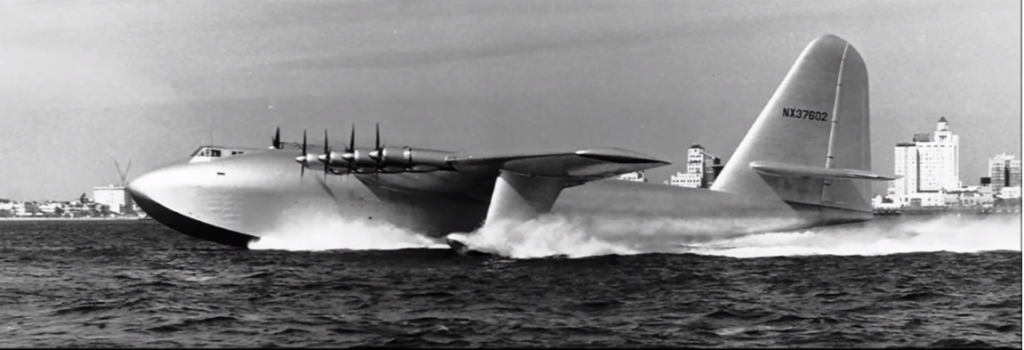

Yano said he was inspired in his research by a photo of the “Spruce Goose”, a cargo plane made almost entirely of wood in 1947 by U.S. billionaire entrepreneur Howard Hughes. At the time, it was the world’s largest aircraft.

“I thought that if Howard Hughes could find a way to use wood to build a massive plane, why not use wood to make a material that was as strong as steel,” he said.

Analysts say high-tensile steel and aluminum will be the more popular alternative for many years to come, considering parts makers would need to overhaul production lines and figure out ways to fasten new materials like cellulose nanofiber onto other car parts.

Anthony Vicari, an applied materials analyst at Lux Research in Boston, said it “would be a big deal” though if Yano’s projections prove to be correct. But for now, it remains “a very big ‘if’”, he said.

Meet the Author

Dr. Todd Shupe is the President of Wood Science Consulting, LLC. He is a well-recognized expert on wood forensics, wood preservation, wood decay and degradation, and wood species identification. He has a broad background in new product development, quality management, and marketing and sales in both the public and private sectors. For more information please visit DrToddShupe.com.

We welcome your comments below.

Thank you for visiting. We trust that you have enjoyed reading our articles.

Liked this post? Read more below or search for more topics . . .