Wood Forensics – Failure Analysis

Wood is unique as a structural material because of its elastic range, biological degradability, and anisotropic nature. Therefore, in service failures involving wood involves a variety of disciplines. Due its elastic nature, we can apply a one-time load to wood within its elastic range and any deformation (i.e., deflection due to bending) is recoverable once the load is removed. Once the elastic limits are exceeded then irreversible changes will occur. For example, a crack results when the applied stress is greater than the elastic limits.

Many in service problems and failures of wood and wood structures are largely the result of fatigue. Fatigue is due to cyclic loading that results in progressive localized irreversible change in a material, which often manifests in cracks or complete fracture if the conditions remain. Once a fatigue crack has initiated, each loading cycle will grow the crack a small amount. So, over time as the condition repeats the crack will increase but ultimate failure of the member depends on many factors such as the location and severity of the crack(s).

Fatigue properties are generally of little concern in many applications of wood but can become important in applications where there are many repetitions (dynamic loading) of stress.

Fatigue failures can occur in furniture construction, especially at the joints, although member failures due occur to a lesser extent. Failure of the side rail to back post joint in chairs is one example. Failure of solid wood furniture parts is less common than joint failures because member strength to joint strength ratios is normally high. Dynamic loading occurs with structures such as chairs, particularly rocking chairs. The joints are repeatedly stressed as the load shifts with each rocking motion. Chairs in a public setting are repeatedly used throughout the day. Each time a person sits, the chair is “loaded” and then “unloaded” as the person stands.

Also, a roof is dynamically loaded in some climates with a snow load. The snow melts as the temperature increases and the roof is unloaded. The process will repeat multiple times throughout the winter.

A severe example of wood fatigue can be found in bridge timbers, piles, and railroad crossties and switch ties. These cases are unique because the loads are severe and can occur frequently. Also,

there is a greater chance of biological degradation with wood in exterior applications, particularly if the wood is in ground contact.

The fatigue strength is always less than the static strength of wood. Years ago, wood was once widely used in the aircraft industry, and fatigue was then considered insignificant or at least covered by safety factors accounting for creep, which is a permanent sag (the elastic limit has been exceeded) in a wood member due to stretching of the wood fibers due to a constant applied load and/or the weight of the member itself. Creep usually develops over years. The classic example of creep is sagging of an overloaded bookshelf which gradually occurs over time.

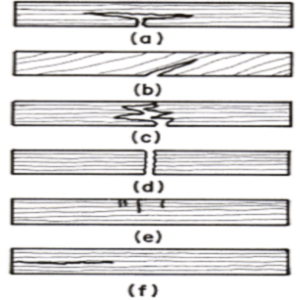

One interesting piece of information to understand wood failure is the mode of fracture. Decay will also affect the mode of failure. The image above shows the failure types of clear wood in bending with span parallel to grain: (a) simple tension, (b) cross-grain tension, (c) splintering tension, (d) brash tension, (e) compression, (f) horizontal shear. There are different failure modes for wood loaded in tension or compression.

Light microscopy or scanning electron microscopy can be useful to examine the cell walls near a failure. The morphology of the walls will help determine if failure was due to static or dynamic loading. Also, a microscopic analysis can sometimes help determine the primary mode of stress loading and any degradation of the cell wall due to wood destroying fungal hyphae (Basidomycota).

Although wood is the world’s most widely used structural material both (by volume and value) its behavior there are many characteristics that are not fully understood. A forensic analysis of a wood failure requires a comprehensive knowledge of wood science and basic engineering principles.

Meet the Author

Dr. Todd Shupe is the President of Wood Science Consulting, LLC. He is a well-recognized expert on wood forensics, wood preservation, wood decay and degradation, and wood species identification. He has a broad background in new product development, quality management, and marketing and sales in both the public and private sectors. For more information please visit DrToddShupe.com.

We welcome your comments below.

Thank you for visiting. We trust that you have enjoyed reading our articles.

Liked this post? Read more below or search for more topics . . .

Go to Recent Posts

Go to All Blogs

Facebook

Twitter

Linkedin